REPLACEMENT AIRPORT WINDSOCKS

Our premium vinyl-laminated polyester airport windsocks are designed for durability and longevity. The material is UV-resistant and weatherproof, ensuring it withstands harsh outdoor conditions while maintaining vibrant color. Our airport windsocks are equipped with solid brass grommets, which offer strong, corrosion-resistant attachment points, making installation secure and easy. Ideal for aviation, industrial, or recreational use, these windsocks provide reliable wind direction indication in various environments.

-

ORANGE WINDSOCK

Vendor:SCOTTS WINDSOCKS LLC5.0 / 5.0

(4) 4 total reviews

Regular price From $40.42Regular priceUnit price / per -

STRIPED WINDSOCK

Vendor:SCOTTS WINDSOCKS LLCRegular price From $51.54Regular priceUnit price / per -

WHITE WINDSOCK

Vendor:SCOTTS WINDSOCKS LLCRegular price From $40.42Regular priceUnit price / per -

Windsock FRAMES double ball bearing

Vendor:SCOTTSWINDSOCKS.comRegular price From $75.85Regular priceUnit price / per

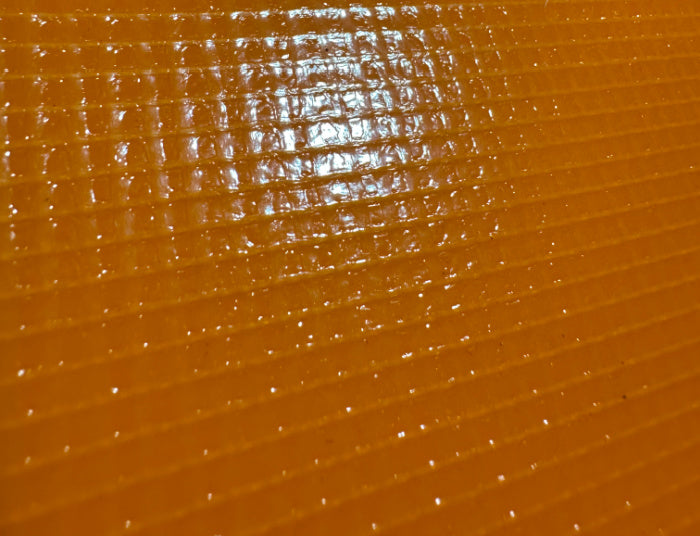

PREMIUM MATERIALS

“Our vinyl laminated polyester material is the best choice for airport windsocks because it combines durability with flexibility. The vinyl coating provides excellent resistance to harsh weather conditions, UV rays, and abrasion, ensuring the windsocks maintain their vibrant colors and structural integrity over time. The polyester base offers a lightweight yet strong fabric that performs well in both high and low wind environments, allowing for optimal airflow and accurate wind direction indication. This combination of features makes our material ideal for reliable, long-lasting windsocks in any setting.”

SOLID BRASS GROMMETS

“Scott’s Airport Windsocks uses solid brass grommets for their exceptional strength and resistance to rust and corrosion. These high-quality grommets ensure secure installation and longevity, even in harsh outdoor conditions, making our airport windsocks a reliable choice for any environment.”

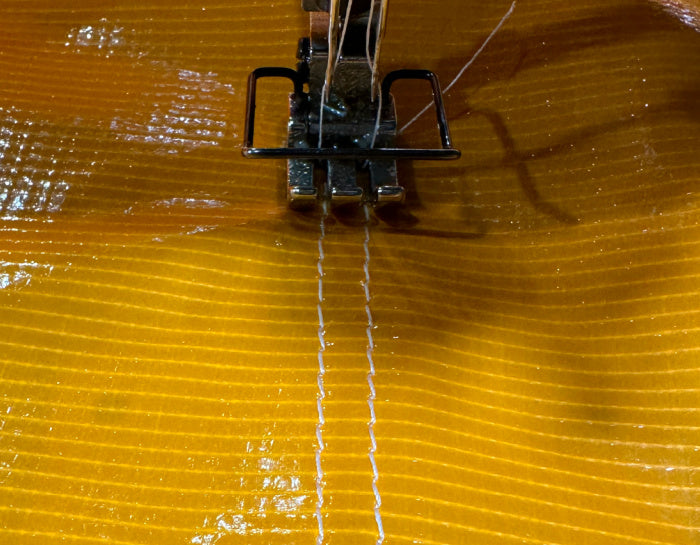

ALL SEAMS DOUBLE STITCHED

“Scott’s Windsocks uses double-stitched seams to ensure maximum durability and strength in all our airport windsocks. This extra reinforcement helps them withstand harsh weather conditions, providing long-lasting performance and reliability you can count on.”

PRECISION CUT FOR ACCURACY

Scott’s Windsocks uses a precision CNC machine to cut windsocks to ensure consistent quality and accuracy in every piece. The CNC machine allows for precise cutting of the vinyl laminated polyester fabric, producing clean edges and uniform shapes that optimize performance. This process reduces material waste and increases production efficiency, ensuring that each airport windsock meets high standards for durability and functionality. The precision also helps maintain the windsock’s structural integrity, making it more resistant to fraying and wear over time.

WINDSOCK FRAMES

Scott’s Windsocks offers the most durable and reliable Metal Double Ball Bearing Windsock Frames in the industry. Engineered for smooth, unrestricted rotation, our frames are built with high-quality, corrosion-resistant materials to withstand extreme weather conditions. The dual-sealed ball bearing system ensures effortless movement in even the lightest winds, providing precise wind direction readings for aviation, industrial, and recreational applications.

Our frames are designed for easy installation and are compatible with standard windsock sizes. Unlike inferior models that seize up or wear out over time, Scott’s Windsocks frames are built to last. We stand behind our craftsmanship with the only 10-year industry warranty, a testament to our commitment to quality and longevity.

When reliability matters, trust Scott’s Windsocks—the leader in durable, precision-engineered windsock solutions.

What our customers are saying...

-

05/2025

" Best windsock on the market. Last longer than three other manufacturers and competitively priced. It been my go to windsock for over 30 years."

Thomas Vaughn -

"This is the absolute best airport windsock made. I have tried all others on this site and they may last up to 6 months before they tear. The Scott's Windsock has lasted 3 years in the wind and sun of south Texas!!! Outstanding product!!"

Boerne S

-

04/2025

"Good quality and fast shipping. Very happy with the windsock."

David Dawley

WHY CHOOSE SCOTTS AIRPORT WINDSOCKS

For 50 years, Scott’s Windsocks has been dedicated to delivering quality and reliability. Our decades of experience have allowed us to perfect our craft, providing durable airport windsocks that customers trust for safety and performance. This long-standing commitment to excellence drives us to continue setting the standard in windsock manufacturing.

"Blue Skies"

-

MADE IN THE U.S.A

-

FAST SHIPPING

-

PREMIUM MATERIALS